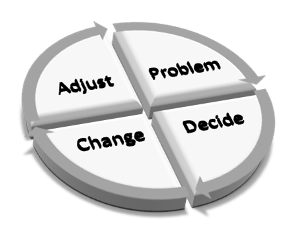

The 10 Minute Kaizen - A Simple Improvement Method for Everyone

- Decide what problem to fix

- Do something new or differently

- Check to see if it helped

- Capture and standardize the new practice

Ten Minute Kaizen, A Simple Improvement Method for Everyone

A Lean term for a [Quality Circle]? Perhaps. But with one very large difference. The ten minute kaizen is meant for the individual as well as a team.

I'm always amused at how we (quality professionals) put a new coat of paint on something and magically come up with a 'new' practice. A Kaizen improvement, how is that different from a directed process improvement effort? Or Kaizens are taking as long as DMAICs (Six Sigma's term for an improvement cycle, Define, Measure, Analyze, Improve and Control), so we come up with a 'Kaizen Blitz', twice the improvement in half the time!

While focusing on small and medium sized organizations, it became quite clear to me that many businesses in this area don't want to invest that much time in an improvement effort. They literally cannot afford the overhead that typically goes a long with many of these practices. So Six Sigma can't help right? They like Lean because it's simple to understand and seems lighter weight. But when faced with a two to three day Kaizen blitz cycle, they don't have that much time. What should they do?

Ten Minute Kaizen

The 10-minute Kaizen can be done by anyone in less than ten minutes and have a lasting effect on how they get things done. It centers on personal accountability, expecting everyone to take responsibility for their work improvement and job satisfaction. It puts the flexibility of the worker back into the work process and makes sure that praise and accountability go hand in hand.

Here's how it works, for every individual and work 'shift', ask these questions:

At the beginning

- What is the most important problem I am having?

- What can I do differently to remove the problem or reduce its' impact

- How will I know it's improved?

During the shift

- Am I executing differently per my earlier decisions?

At the end

- Did I improve the problem area today?

- If so, how have I captured the change to make sure we do this every time?

Simple right? Seems like common sense. But as we know, common sense is not always common practice.

Why a Ten Minute Kaizen?

PROBLEM: At the beginning, evaluating the most impactful pain point is best done by those that are executing the tasks everyday.

DECIDE: Asking those performing the work for their innovative ideas and encouraging them to embrace and execute them creates a culture of accountability that will assure that they're doing their best and taking responsibility for the outcomes. Encouraging the idea of 'measuring for success' will help them understand what success looks like, and give management the ability to quantitatively (without subjective opinion) see if the changes are making a positive impact.

CHANGE: Holding themselves accountable to the new way of doing things reinforces that they are responsible for the outcomes of what they deliver AND improving how they do it.

ADJUST: Reinforcing that some things work and some don't seems like common sense, but I can't tell you how many times I've heard, "Why do you do it that way?" - "Because that's the way it's always been done." So creating a process that actively identifies what to throw away and what to keep (standardize) keeps people's brains engaged.

Of course, the 10 minute Kaizen does not eliminate the responsibility of the manager or supervisor. And assuring that the improvements discovered don't damage the process more than they help is still the responsibility of the manager, or better, the team.

Recap

The 10 minute Kaizen can be done by everyone in the organization. It takes very little training. Organizations get more effective and efficient operations. The workforce is more engaged because they are actively taking part in the daily decisions. It's easy to understand and can have a lasting impact not only on the work, but also on those that perform the work.

So have we come full circle? Is this just another name for a Quality Circle? What do you think?

- Chris's blog

- Login or register to post comments

-

Printer-friendly version

Printer-friendly version Post to Twitter

Post to Twitter- Send by email

- PDF version

Recent Updates

Microsoft Outlook Add-In

Focus on Your Life, Not Your Inbox

Achieve greater focus by shifting your attention from e-mail to accomplishing what matters most!

Company News

Stay up to date with our newsletter!